Product Information

01.Product Features

Characteristics of our flexible container bag

01

Design to meet customer needs

We do development, design, prototype, evaluation and mass production after thoroughly studying distribution system such as filling environment, on-premises transportation, shipping for customer's flexible container bag.

02

Domestic product development and overseas production

We provide optimal specifications with the shortest delivery time by flexible container bag product development in Japan and prototype making, performance test and mass production in our overseas factories.

03

Continuously cost reduction

We thoroughly control the cost of our own factory, eliminate unnecessary waste, strive to reduce the defect rate and improve the yield, and do what can be done locally at the local site, achieving a thorough cost reduction by establishing a head office structure with a minimum number of staff.

04

Lean distribution management

In place of stock management of customer's flexible container bags, established a just-in-time supply system. We deliver containers directly to customers as well.

05

Assortment of high-level flexible container bags

There are many achievements in the production of flexible containers such as new JIS standards, high cleanliness specifications, food specifications, UN standard compliant, conductive specifications, and anti-electrostatic specifications. In addition, it is also possible to supply single items such as inner bags for flexible containers (aluminum inner bags, conductive inner bags, anti-electrostatic inner bags).

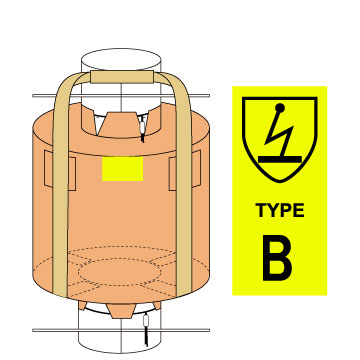

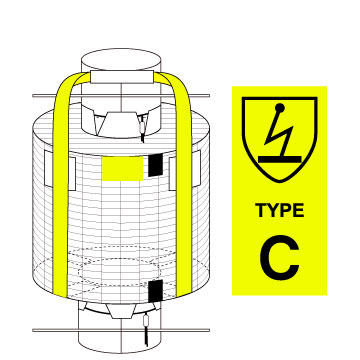

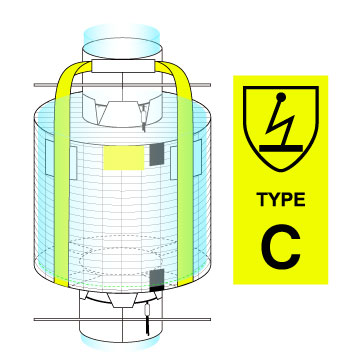

Electrostatic measures flexible container bags

Electrostatic measures flexible container bags are made to prevent disasters such as dust explosion caused by electrostatic discharge when filling and discharging. There are three types of them (type B, C, D) classified by discharge prevention mechanism. On the other hand, normal flexible container bags which are made without any special electrostatic measures are called type A. We offer all types of electrostatic measures flexible container bags. (type B to type D) They can be used safely even in an environment where dust explosion may occur.

Products of flexible container bags

Type A:Normal flexible container bags are made without any special electrostatic measures.

Type B:They are designed to suppress the generation of creeping discharge. They can be used in an environment where measures against electrostatic disasters are taken and a dusty environment ignition energy exceeds 3mJ.

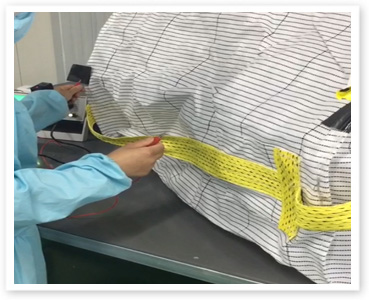

Type C:The flexible container bags are made of mixed fabric in which carbon steel or conductive yarn with a silver core are woven at regular intervals. Our system is designed to quickly reduce static electricity generated when filling and discharging granular materials, and not to store energy that could lead to disasters. We check all products for conductivity after inspection and before shipping.

Type D:They are made from safety designed materials which prevent brush discharges and creeping discharges and do not need grounding. This type of flexible container bag produces corona discharges before producing brush discharges or creeping discharges when the bags get electrified and then the conductor approaches. Corona discharge does not set a fire because it’s a very weak discharge with almost no sound or light, also referred to as silent discharge. The flexible container bags are made for complete protection against the danger of electrostatic and don’t need to ground.

Inner bags type

The combination list of electrostatic measures flexible container bags and inner bags

| Inner bags type | Inner surface resistivity | Outer surface resistivity | Dielectric breakdown voltage | Thickness | Possible combination of flexible container bags |

|---|---|---|---|---|---|

| L1 | 1.0×107 or less | 1.0×107 or less | No measurement required | No limit | C |

| 1.0×107 or less | 1.0×1012 or less | No measurement required | No limit | ||

| 1.0×1012 or less | 1.0×107 or less | No measurement required | No limit | ||

| 1.0×107 or less | More than 1.0×1012 | Less than 4kV | No limit | ||

| More than 1.0×1012 | 1.0×712 or less | Less than 4kV | Less than 700μm | ||

| L2 | 1.0×107 - 1.0×1012 | 1.0×109 - 1.0×1012 | No measurement required | No limit | B,C,D |

| 1.0×107 - 1.0×1012 | More than 1.0×1012 | Less than 4kV | No limit | ||

| More than 1.0×1012 | 1.0×109 - 1.0×1012 | Less than 4kV | Less than 700μm | ||

| L3 | More than 1.0×1012 | More than 1.0×1012 | Less than 4kV | No limit | B |

Case 1

Inner bags type:L1

Inner surface resistivity:1.0×107 or less

Outer surface resistivity:1.0×107 or less

Dielectric breakdown voltage:No measurement required

Thickness:No limit

Possible combination of flexible container bags:C

Case 2

Inner bags type:L1

Inner surface resistivity:1.0×107 or less

Outer surface resistivity:1.0×1012 or less

Dielectric breakdown voltage:No measurement required

Thickness:No limit

Possible combination of flexible container bags:C

Case 3

Inner bags type:L1

Inner surface resistivity:1.0×1012 or less

Outer surface resistivity:1.0×107 or less

Dielectric breakdown voltage:No measurement required

Thickness:No limit

Possible combination of flexible container bags:C

Case 4

Inner bags type:L1

Inner surface resistivity:1.0×107 or less

Outer surface resistivity:More than 1.0×1012

Dielectric breakdown voltage:Less than 4kV

Thickness:No limit

Possible combination of flexible container bags:C

Case 5

Inner bags type:L1

Inner surface resistivity:More than 1.0×1012

Outer surface resistivity:1.0×1012 or less

Dielectric breakdown voltage:Less than 4kV

Thickness:Less than 700μm

Possible combination of flexible container bags:C

Case 6

Inner bags type:L2

Inner surface resistivity:1.0×107 - 1.0×1012

Outer surface resistivity:1.0×109 - 1.0×1012

Dielectric breakdown voltage:No measurement required

Thickness:No limit

Possible combination of flexible container bags:B,C,D

Case 7

Inner bags type:L2

Inner surface resistivity:1.0×107 - 1.0×1012

Outer surface resistivity:More than 1.0×1012

Dielectric breakdown voltage:Less than 4kV

Thickness:No limit

Possible combination of flexible container bags:B,C,D

Case 8

Inner bags type:L2

Inner surface resistivity:More than 1.0×1012

Outer surface resistivity:1.0×109 - 1.0×1012

Dielectric breakdown voltage:Less than 4kV

Thickness:Less than 700μm

Possible combination of flexible container bags:B,C,D

Case 9

Inner bags type:L3

Inner surface resistivity:More than 1.0×1012

Outer surface resistivity:More than 1.0×1012

Dielectric breakdown voltage:Less than 4kV

Thickness:No limit

Possible combination of flexible container bags:B

- *L1、L3→23±2℃ and relative humidity 20±5%.

- *L2→23±2℃ and relative humidity 20±5%, 23±2℃ and relative humidity 60±10%.

- *When the L2 inner bag is used in type C, the generated current must not exceed 3μA.

- Click here for details on electrostatic measures flexible container bags.

Standards for Food Sanitation Law / Food / Addictives

We conduct regular inspections of standard material of flexible container bags and inner bags for food, based on the notification "Material standards for synthetic resin tools or containers and packaging (Ministry of Health and Welfare Notification No.370)." Our standard material shows the conformity value in all standards, so it can be used safely for customers who want to use it to contain food or feed crop.

Additive-free plastic bags for food and pharmaceutical products

We also produce flexible container bags combined with additive-free plastic bags for food and pharmaceutical products at customers’ request. LDPE and LLDPE are mainly used for the inner plastic bags of flexible container bags. Basically, the additive-free material is radical polymerization type of LDPE. On the other hand, because of ionic polymerization, LLDPE uses a catalyst for reactions such as inflation. General LLDPE uses a chlorine-based catalyst. However, calcium chloride and stearic acid are generated because chlorine is corrosive and “calcium stearate” is also added for neutralization.

We propose non-additive plastic bags to avoid dissolution of such substances and get into the contents. We also propose flexible container bags which combines composite specification aluminum inner bags for contents that are vulnerable to moisture. The sealed aluminum inner bags can completely protect the contents from moisture. In addition, in terms of high water content, aluminum inner bags has a low oxygen permeability, so it’s possible not only to prevent leakage of the contents, but also prevent the progress of some fermentations.

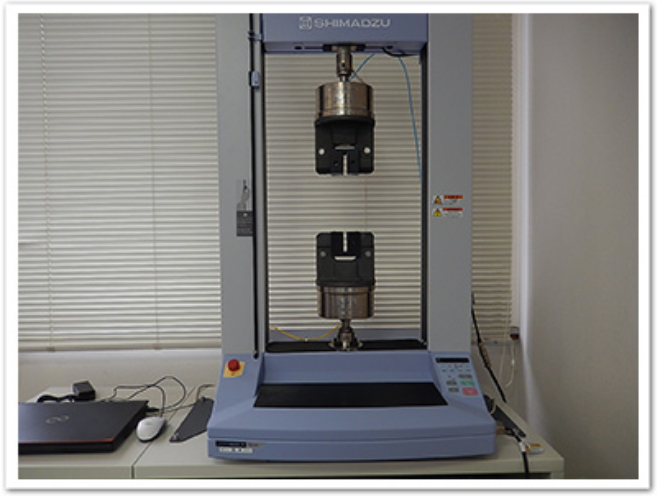

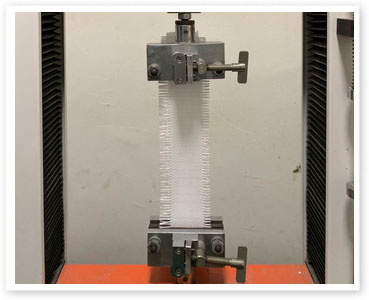

(Various) test machines

In order to supply products that our customers can use safely, we regularly measure every component and product performance of flexible container bags using our testing machines in our company.

Strength tester lifting flexible container bags

Universal strength testing machine

QUV UV fluorescent lamp accelerated weathering tester

Product examples

We design and produce various types of flexible container bags according to customers' request.

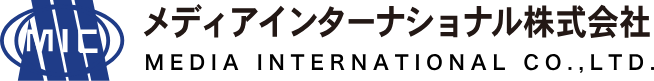

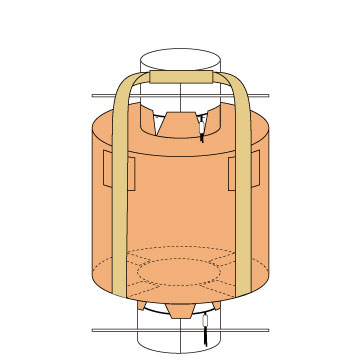

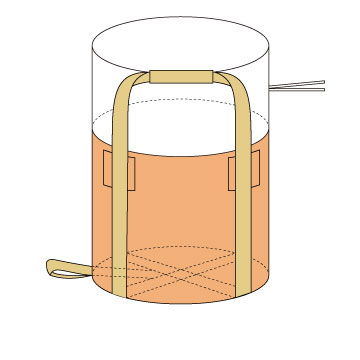

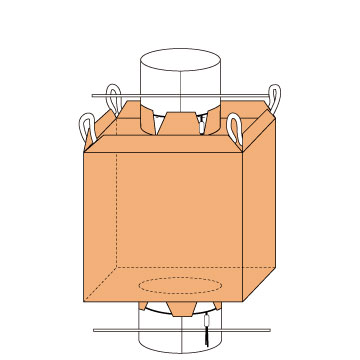

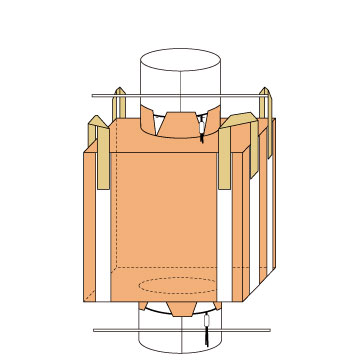

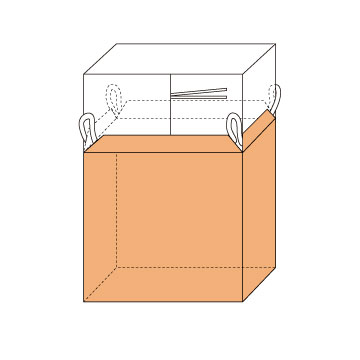

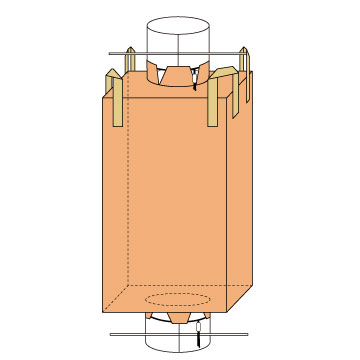

SF01

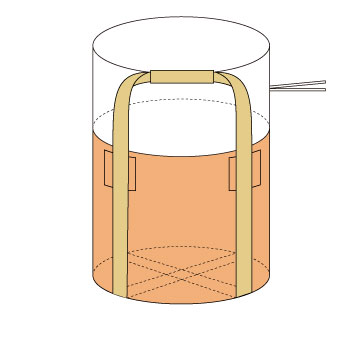

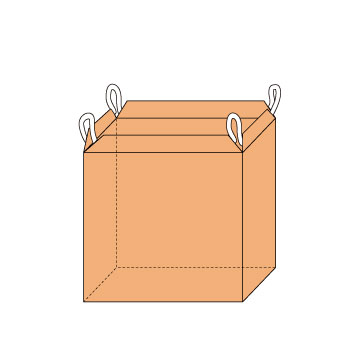

SF02

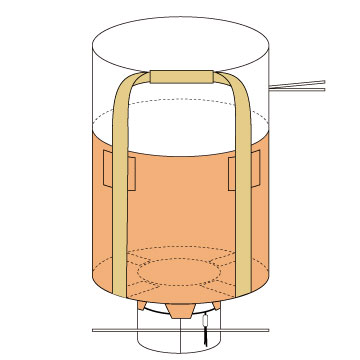

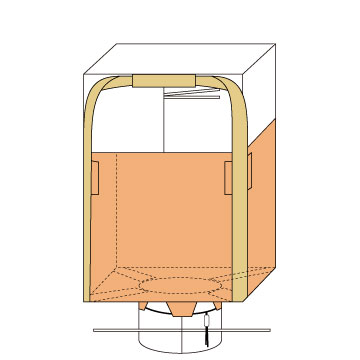

SF03

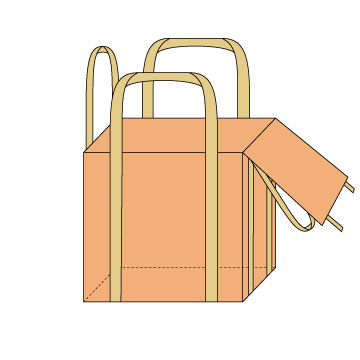

UF01

UF02

02.Quality Assurance

Quality control system

We thoroughly control quality with the following control system of flexible container bag quality.

【Warranty period】

1 year (Count from the delivery date)

*The following conditions are required.

【Storage location of flexible container bags】

Must be indoors, not affected by ultraviolet rays.

【Handling conditions for flexible container bags】

One-time use only. (However, flexible container bags with special specifications are excluded.)

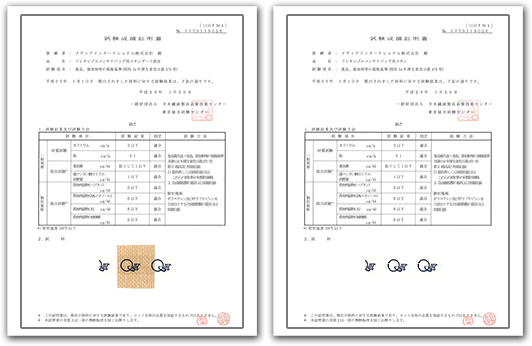

Test report on various certifications and products

ISO9001 certification

(Our manufacturing factory)

Halal certification

(Our manufacturing factory)

New JIS standard test report

Flexible container bag UN test report

Certificate of UV proof large soil bag performance

Weather resistance test report

Food container analysis report

We regularly acquire various standard tests such as JIS and UN (Standard of UN dangerous goods transport) for flexible container bag products. In addition, we obtained ISO9001 at an early stage for the production factory, and in October 2014, we received HALAL certification from the Isramic Food Research Centre Asia (IFRC Asia) in Malaysia in order to support the use of food-related raw materials. An overview of the Malaysian Isramic Food Research Centre Asia (IFRC Asia) can be found here.

Isramic Food Research Centre Asia (IFRC Asia)

http://www.ifrc-asia.org/

03.Research and Development

Strength test in our factory

JIS Z 1651 standard test of flexible container bag

UN Test for UN transport of dangerous goods

Test of UV proof large soil bag performance

Member strength test

UVB weather resistance test

Type C conductivity test

Original design

04.Application Examples

Application examples of flexible container bags for our customers

Chemicals / Food / Activated carbon / Carbon / Battery material / Salt / Agricultural chemicals / Feed crop / Processing fertilizer / Decontamination waste container / UV proof large soil bag / Conductive flexible container bag / Flexible container bag with partition walls / Shape prevention / Powder leakage prevention / Dust proofing

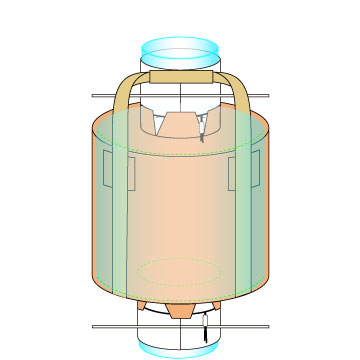

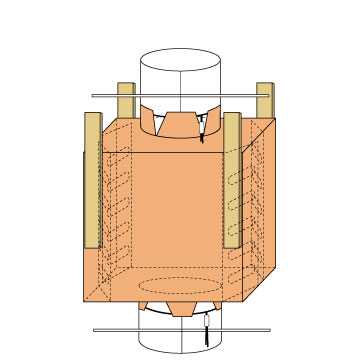

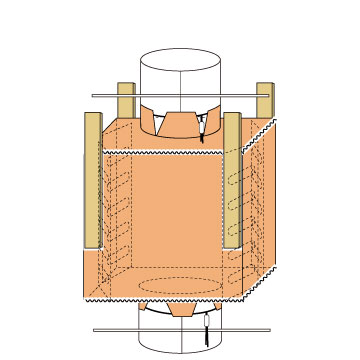

Flexible container bag for general purpose

Long type of flexible container bag

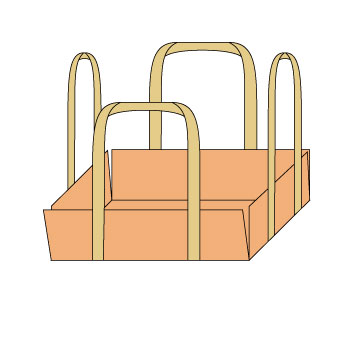

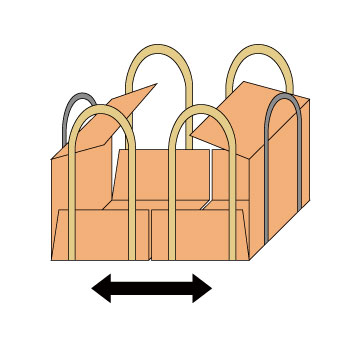

Flexible container bag with shape-prevention partition

Conductive flexible container bag

UV proof large soil bag

Flexible container bag for multi-stack

Unit flexible container bag

Bulk container liner